With the continuous reduction of the size of electronic components and the improvement of functional efficiency, the requirements of heat dissipation electronic components are also improved. An excellent heat dissipation system means higher heat dissipation efficiency and smaller heat dissipation space.

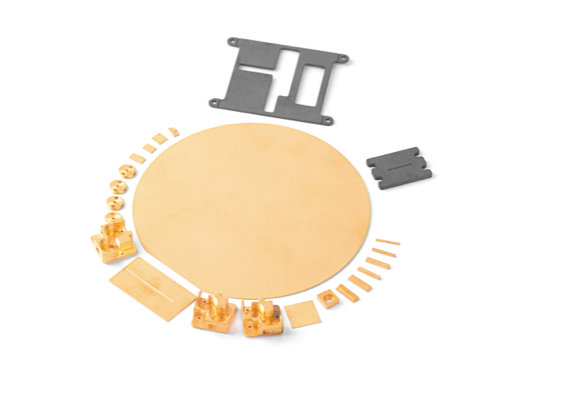

Molybdenum copper, Tungsten Copper, CMC and CPC materials combine the low thermal expansion rate of Molybdenum and Tungstenwith the high thermal conductivity of Copper, which can effectively release the heat from electronic devices and contribute to the reliable and effective release from the heat that is generated by electronic components. It can be used in IGBT modules, RF power amplifiers, LED chips, etc.. Moreover, it also can be used as insulated metal substrate, thermal control boards, heat dissipation elements (heat sink materials) and lead frames in large scale integrated circuits and high-power microwave devices.

Products:

1. Tungsten-Copper alloys

2. Molybdenum-Copper alloys

3. Copper-Molybdenum-Copper (CMC)

4. Copper-Molybdenum Copper-Copper (CPC)

5. Aluminum Silicon Carbide material (AlSiC)

6. Silicon Aluminum (AlSi)

7. Copper/Kovar/Copper, Copper/Invar/Copper, Copper/Steel/Copper

1. Tungsten-Copper alloys

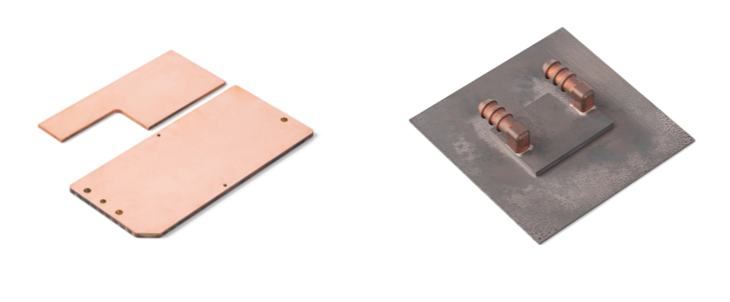

Fully combining the characteristics of high thermal conductivity, high melting point, low thermal expansion coefficient of Tungsten and high thermal conductivity of Copper, the ratio of Tungsten to Copper can be adjusted at will. We provide Tungsten Copper alloys which can be almost completely compact, defect-free and fine grains structure, materials of air tightness of helium mass spectrometer leak detection is less than 5*10-9Pa‧m3/s. Weguarantee of accuracy of precise processing, surface smoothness and flatness. We also provide Tungsten-Copper sheet and electroplated products for your needs.

Typical properties and values for our Tungsten-copper alloys materials:

2. Molybdenum-Copper alloys

Compared to Tungsten-copper alloys, Molybdenum-copper alloys has smaller density and better ductility, which leads to thinner products. The Molybdenum-copper alloys can be pressed and is suitable for the massive production and low cost heat sink parts. Purex Metal's Molybdenum-copper alloys is almost completely compact, defect-free, and fine grains structure. Materials of air tightness of helium mass spectrometer leak detection is less than 5*10-9Pa‧m3/s. We guarantee of accuracy of precise processing, surface smoothness and flatness. We also provide Molybdenum-copper sheet and electroplated products for your needs.

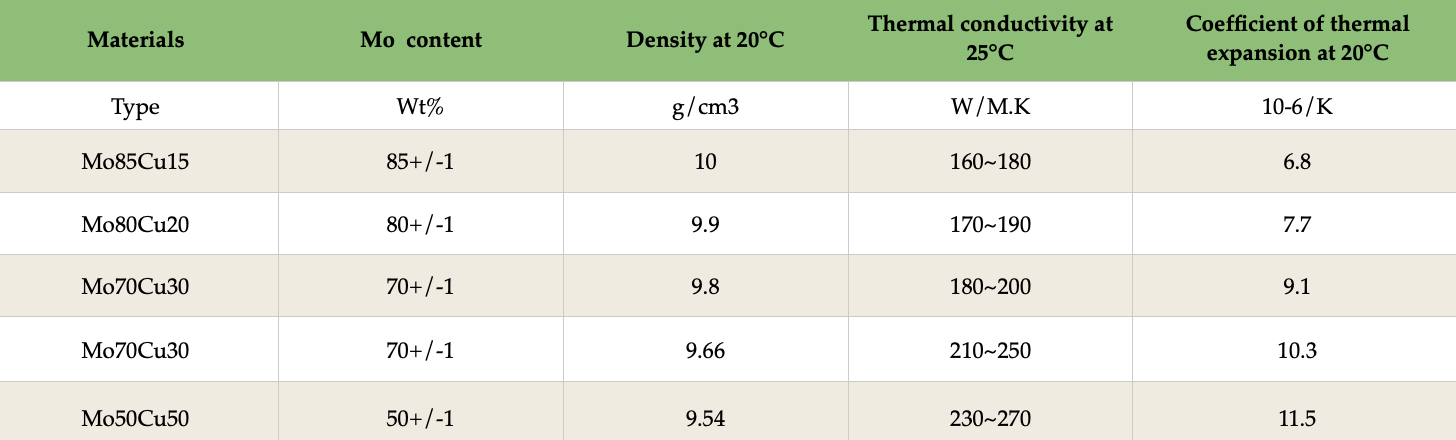

Typical properties and values for our Molybdenum-copper alloys materials:

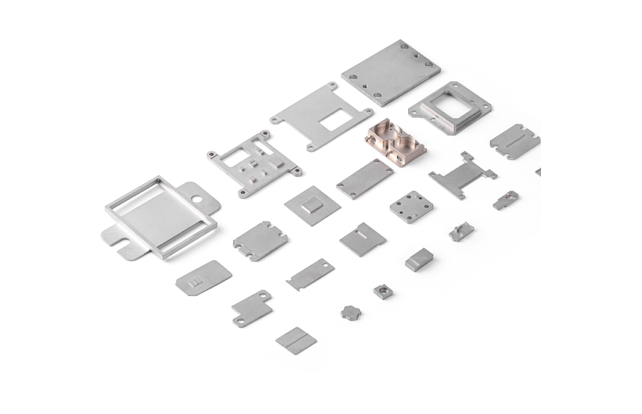

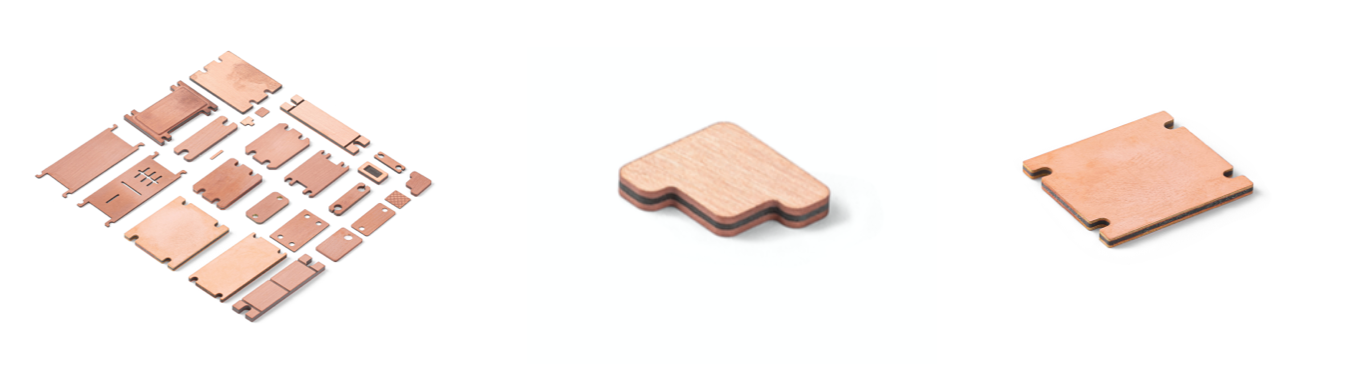

3. Copper-Molybdenum-Copper (CMC)

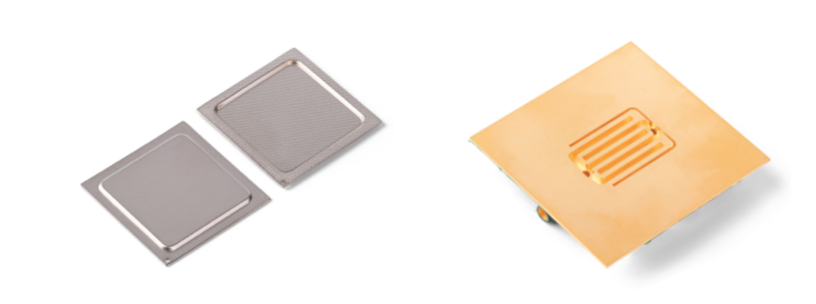

CMC is a three-layer structural material with core of Molybdenum and double-side coated with Copper. With its lower thermal expansion coefficient and thermal conductivity than WCu and MoCu, it becomes a better replacement scheme for high-power electronic heat spreaders components, which is helpful for cooling IGBT module and other high-power components. CMC can be pressed into sheet parts, or be made from heat pipe products. We can provide you with different thermal expansion coefficient products by adjusting the thickness ratio of CMC materials.

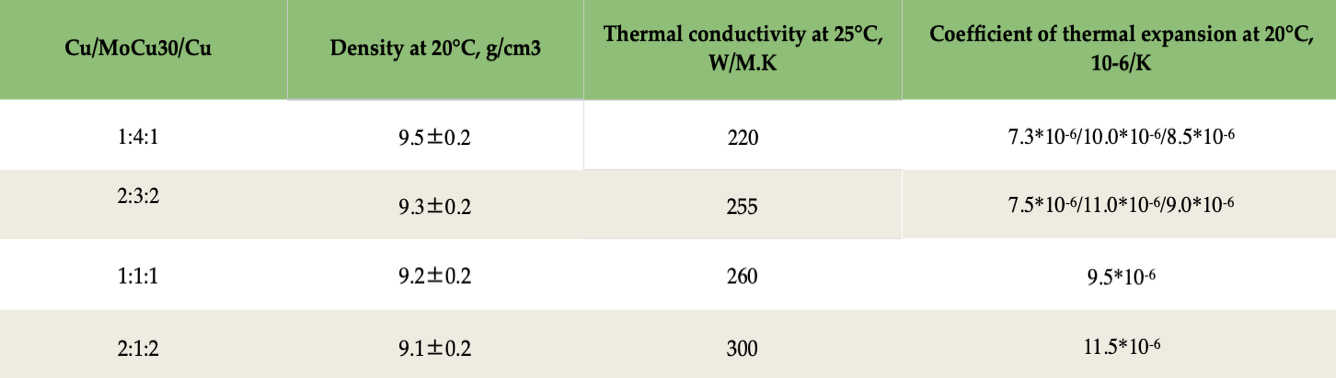

Typical properties and values for our CMC materials:

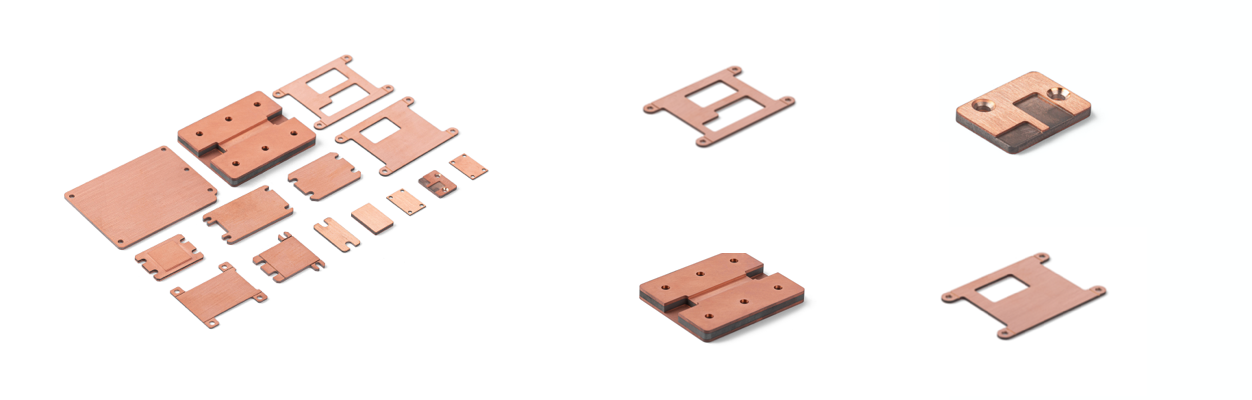

4. Copper-Molybdenum Copper-Copper (CPC)

CPC is a sandwich structure composite material which is similar to CMC, the core material is Molybdenum Copper alloys, double-side coated copper. The thermal conductivity of CPC material is higher than CMC, and the expansion coefficient of CPC in X and Y directions can be adjusted due to the variable and adjustable of the core material of Molybdenum Copper particles.

Typical properties and values for our CPC materials:

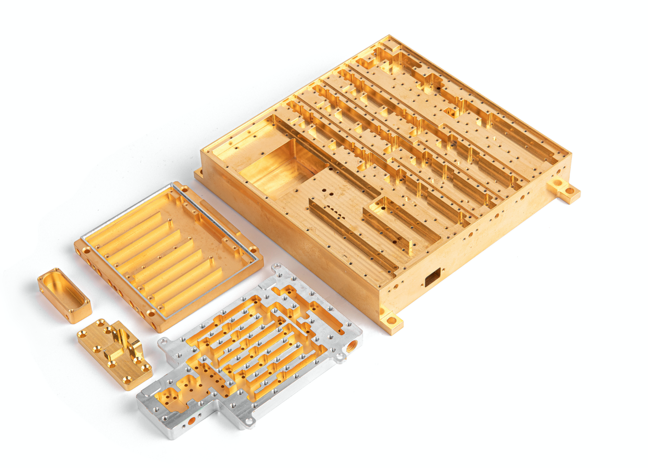

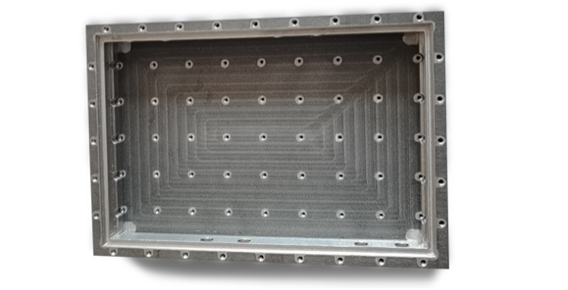

5. Aluminum Silicon Carbide material (AlSiC)

Aluminum Silicon carbide composite material is a new material composed of silicon carbide ceramics and Aluminum, which has high thermal conductivity, low thermal expansion coefficient, good specific stiffness and light weight. It is an ideal power electronic substrate material and substrate material, which can achieve good match with electronic chips after welding. IGBT products encapsulated by Aluminum Silicon carbide substrate are widely used in high-speed railway drive, subway drive, new energy vehicles, wind power generation, welding robot industry etc..

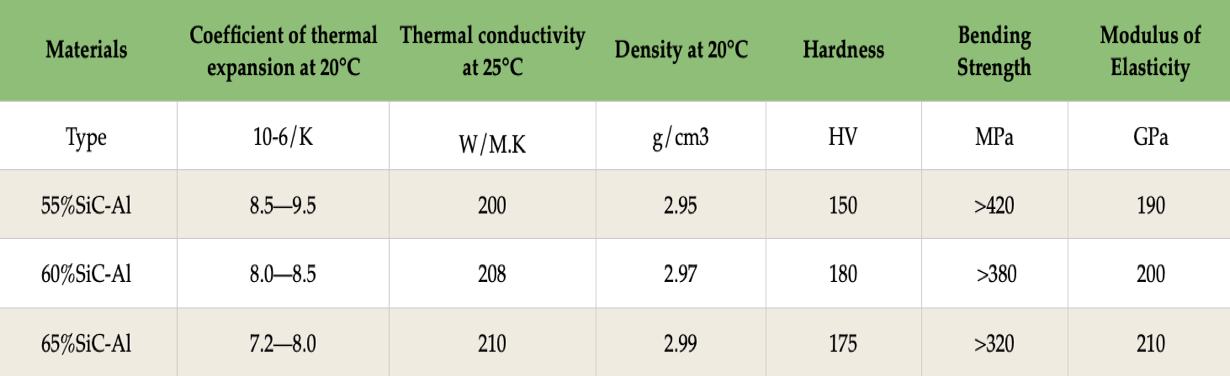

Typical properties and values for our AlSiC materials:

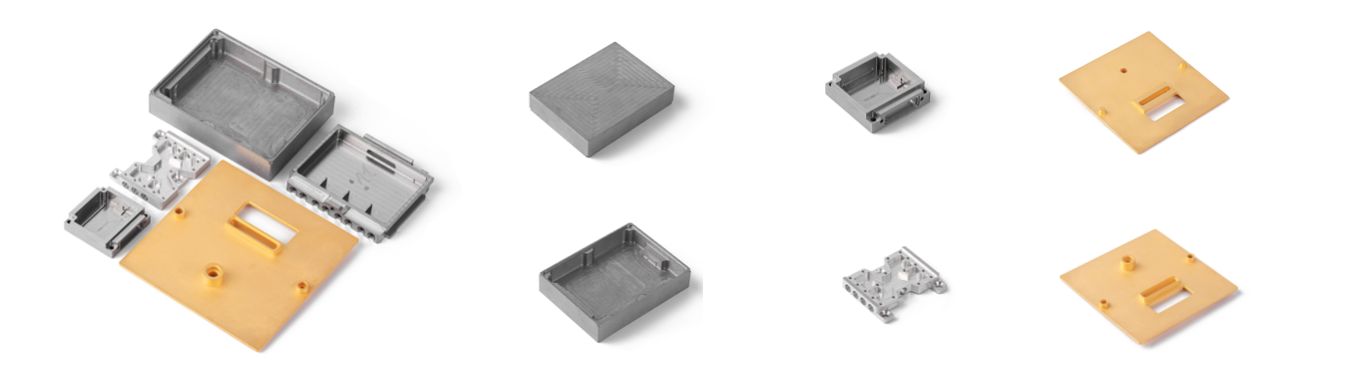

6. Silicon Aluminum (AlSi)

Aluminum Silicon carbide composite material is a new material composed of Silicon carbide ceramics and Aluminum, which has high thermal conductivity, low thermal expansion coefficient, good specific stiffness and light weight. It is an ideal power electronic substrate material and substrate material, which can achieve good match with electronic chips after welding. IGBT products encapsulated by Aluminum Silicon carbide substrate are widely used in high-speed railway drive, subway drive, new energy vehicles, wind power generation, welding robot industry etc..

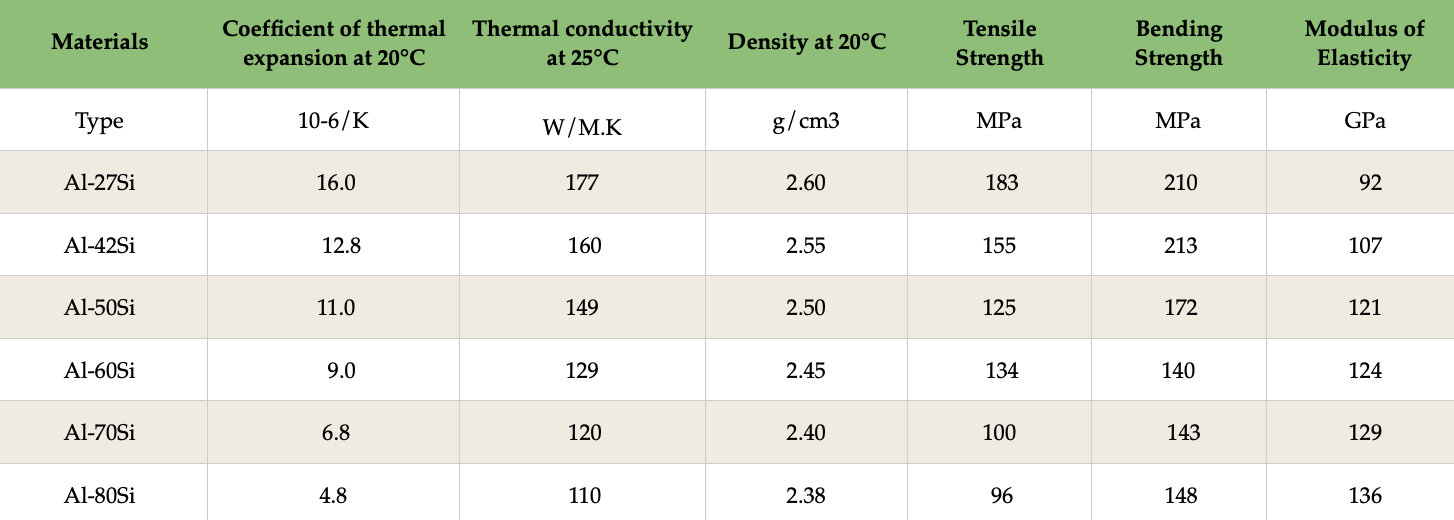

Typical properties and values for our AlSiC materials:

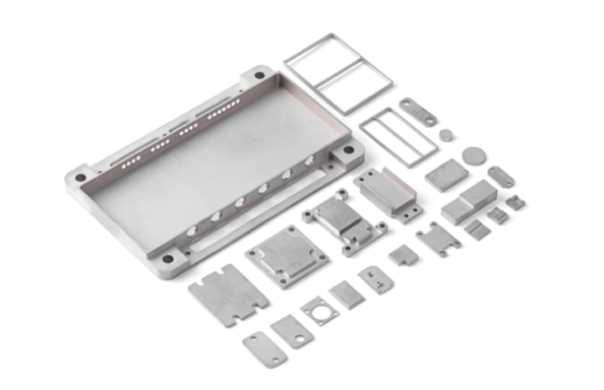

7. Copper/Kovar/Copper, Copper/Invar/Copper, Copper/Steel/Copper

Silicon Aluminum is the replacement of Aluminum Silicon carbide material, with its light weight (density 2.4-2.7g /cm3), high thermal conductivity, low coefficient of thermal expansion, high stiffness, easy machining, good surface plating performance and welding performance, good compactness, high temperature resistance, corrosion resistance etc., but low hardness. Mainly used in microwave power device, integrated power module, T/R module and other electronic power devices.